PP Continuous Fiberglass Reinforced Thermoplastic Cabinet Honeycomb Panel

Basic Info

| Model NO. | panel fiberglass |

| Name | Thermoplastic Honeycomb Panel |

| Area Weight PF Cfrtp Honeycomb Panel | 2.0-8.0 Kg/M2 |

| Core Material of Cfrtp Honeycomb Panel | PP Honeycomb Core |

| Panel Thickness | 8mm-50mm |

| Panel Width of Cfrtp Honeycomb Panel | 0-2700mm |

| Color of Cfrtp Honeycomb Panel | Natural and Black |

| Surface of Cfrtp Honeycomb Panel | Can Be Laminated with Anti-UV, Anti-Aging Film etc |

| Application of Cfrtp Honeycomb Panel | Truck Body, Scaffoldings, etc |

| Resin of Cfrtp Honeycomb Panel | PP, PE, Pet, PETG, PA6.etc |

| Packing Cfrtp Honeycomb Panel | Pallet, Plywood Box, as Customized |

| Place of Origin | Qingdao, China |

| Core Material | PP Honeycomb |

| Advantage | Heat Preservation |

| MOQ | 100sqm |

| Transport Package | Scaffold Panel Packing Nude Packing or Pallet |

| Specification | Scaffold Panel size as per reuqest |

| Trademark | lusafe |

| Origin | China |

| HS Code | 3921909090 |

| Production Capacity | 7000 Square Meters Per Day |

Product Description

PP Continuous Fiberglass Reinforced Thermoplastic Cabinet Honeycomb PANEL

In short, what we could provide:(Click on the name below to reach the corresponding product link)

| 1 | Continuous Fiberglass Reinforced Thermoplastic products, including--Unidirectional tapes--laminate sheet--Honeycomb sandwich panel--Foam Core sandwich paneletc. |

| 2 | Machinery line, which could produce the above products |

| 3 | Factory construction guidance, from 0 to a functioning factory. |

Product Description

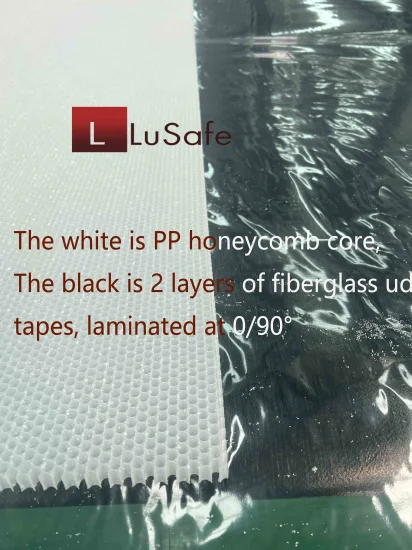

Here below are the Continuous Fiberglass honeycomb panels:

The skin is the CFRP sheet(continuous fiber-reinforced thermoplastic). It contains resin and fibers. The resin acts as a matrix that accounts for 30% to 40% of the total weight. The resin can be PA, PE, PP, epoxy, phenolic, etc. The GRP sheet takes glass fiber as the reinforcement. The alternatives can be carbon fiber and other non-metallic and inorganic fibers. The fiber roughly accounts for 60% to 70% of the total weight. Its core is either plastic foam or plastic honeycomb.

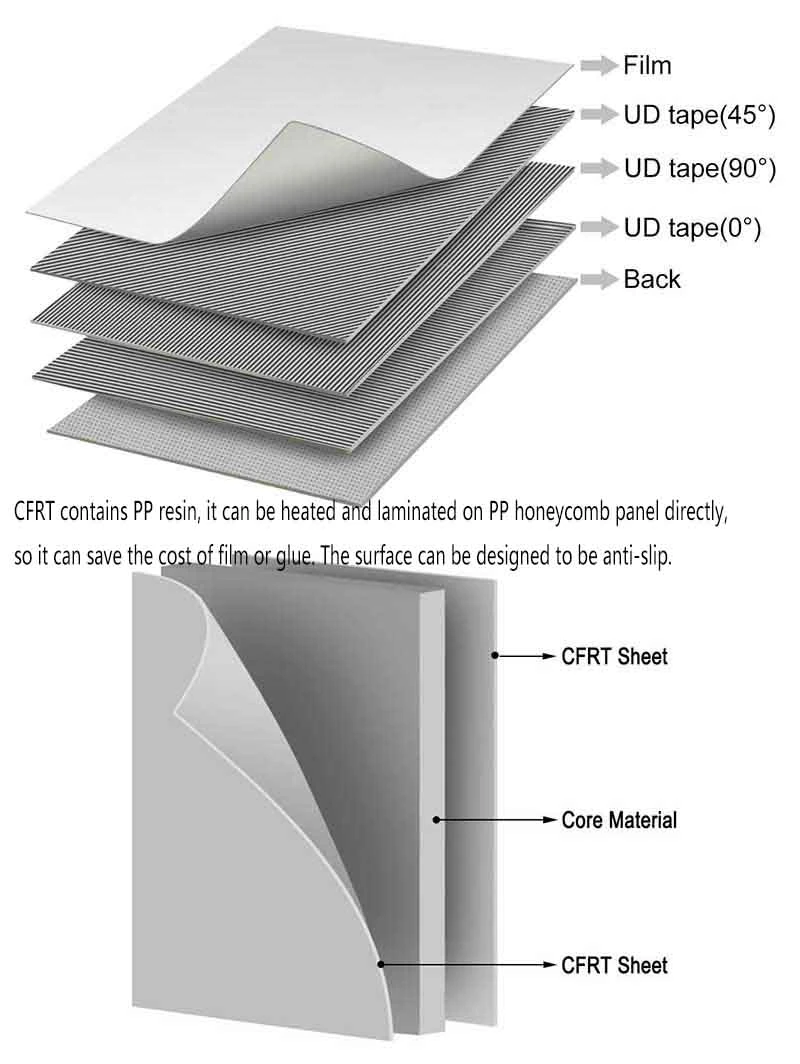

The structure of CFRP Sandwich Panels helps you know more about the sandwich panelThe skin of the panel is made of UD tapes in several directions, named CFRT sheet in the below photos.

CFRT contains PP resin, it can be heated and laminated on PP honeycomb panel directly, so it can save the cost of film or glue. The surface can be designed to be anti-slip.

Product Parameters

What we can provide:

| Type | Fiberglass sheet + Honeycomb core +Fiberglass sheet |

| Core Material | PP Honeycomb core, Aluminum Honeycomb core. |

| Skin Type | CFRT Sheet,2 to 9 layers, |

Panel Width | 0-2700mm |

Thickness | 8mm-50mm |

Length | Customize |

Color | White, Black, or Customized |

| Surface effect | It can be used with anti-ultraviolet and anti-aging films, and can also be laminated with non-woven fabrics and decorative films. |

Application | RVs, trailers, vans, dry vans, refrigerated trucks, campers, building formwork, scaffolding, mobile homes, sports products, truckfloor, etc. |

| Advantage | 1. Lightweight2. Moisture resistance and rust resistance;3. Completely recyclable, environment friendly;4. Excellent compression strength, stiffness, and impact resistance;5. Customizable size and thickness; |

| Leading time | 4 weeks |

Our fiberglass honeycomb panels have the following advantages:

- Low density: Since PP/PC honeycomb is a porous material, the entire panels are lightweight.

- Good sound insulation and heat insulation performance: good sealing performance greatly limits the spread of heat and sound waves.

- Shock absorption: Dense honeycombs and high-strength FRP skin disperse pressure.

- Good flatness and rigidity: Using continuous glass fiber thermoplastic sheet as skin.

Detailed Photos

The surface could be used with anti-ultraviolet and anti-aging films, and can also be laminated with non-woven fabrics and decorative films.

Application

CFRT Fiberglass honeycomb panels could be used in Transportation, Dry van bodies, recreational vehicle floors, Scaffolding, building formwork, etc.

Regular Quality Control

The honeycombed panel on the right is an unqualified product, want to know why? contact us.

Packaging & Shipping

Nude Packaging or Pallet Packing

Recommend Products

CFRTP UD TAPES CFRT laminate sheet Foam Core Panel

If you want to build a factory that produces a continuous fiber-reinforced thermoplastic composite, we could help you.Factory construction guidance, from 0 to a functioning factory.and also regarding the machinery line, we have experienced engineers, we could supply the machinery line.

Company Profile

Choose Lusafe Fiberglass Sandwich Panels

Lusafe fiberglass sandwich panels factory covers an area of tens of thousands of square meters, with a daily production area of more than 10,000 square meters. Our FRP panels are very popular in the international market and sell well in Europe, South America, North America, the Middle East, Central Asia, Southeast Asia, Africa, and other markets.